Product Introduction

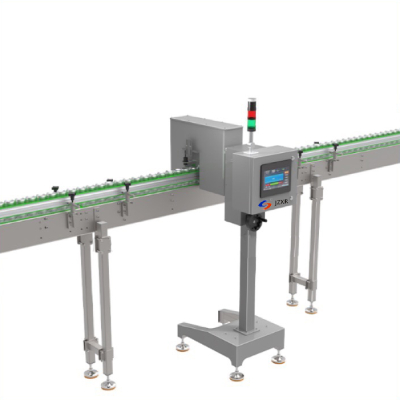

Introducing our advanced X-ray Liquid Level Inspection System with Quick Pusher Rejector, designed to ensure the utmost quality and consistency in your bottled or canned liquid products. Esteemed brands such as Wanglaoji, Budweiser, SMC, and Schneider Electric have partnered with us, underscoring the reliability and superior performance of our product.

Specification

| X-ray Low Liquid Level Detection Sensivity | ≥99.99%(when the detection speed reaches 1200/minute) | |

| False Rejection Rate | ≤0.3% | |

| Product capacity | 220-2000ml(Customized order is acceptable) | |

| Total power | about 2.4kW | |

| Power Supply | 220VAC ±10%, 50/60Hz | |

| Production line conveyor belt speed | ≤1.3m/s | |

| Container diameter | 20mm~125mm(Customized order is acceptable) | |

| Single package size | 185X135X215 cm | |

| Single gross weight | 500.000 kg | |

| X-ray Source | 1W - 50W | |

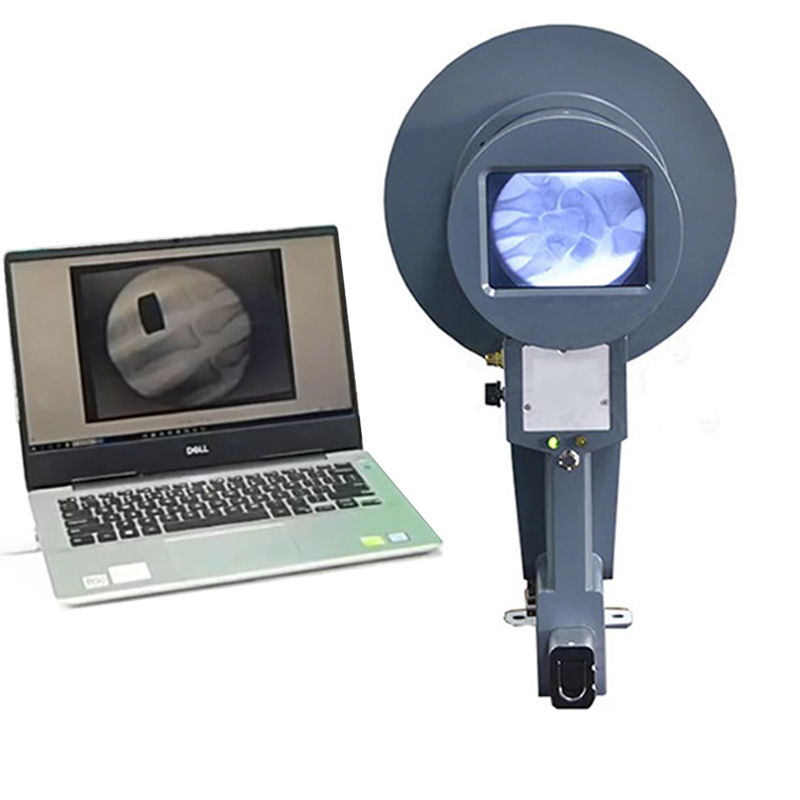

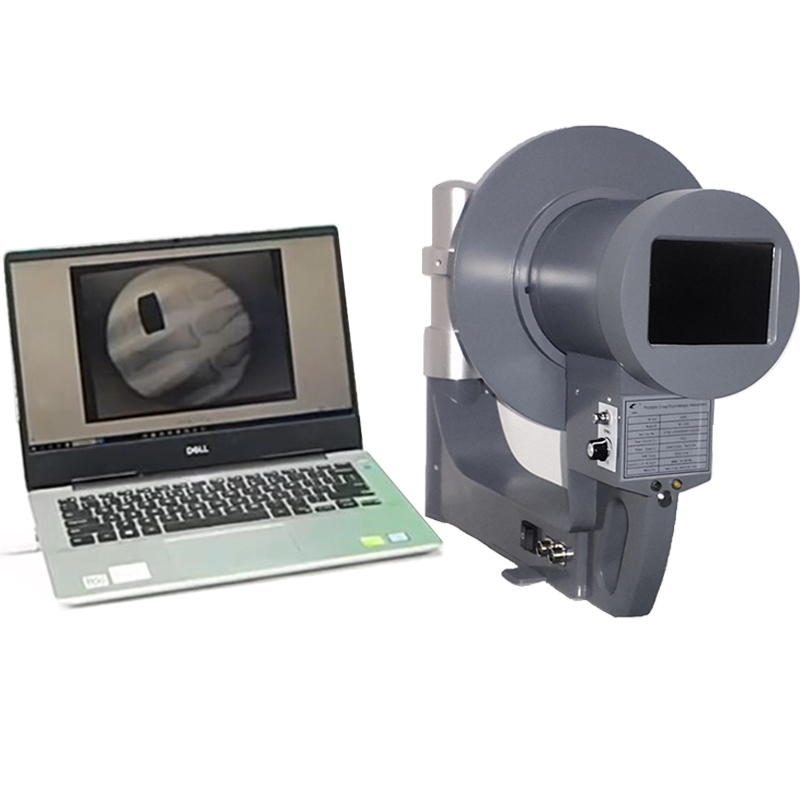

| X-ray Detector | Hamamatsu, Japan | |

| Display Screen | Weinview 10 inch full color touch screen | |

| Software | JZXR (Easy operation and support remote service) | |

| Container material | paper, plastic, aluminum, tinplate, ceramic products, etc. | |

| Maximum Detection Speed | 90,000 BPH | |

| Material of Construction | SUS 304 | |

| Auto rejection system | One Air Jet / Pusher rejector (Included) | |

| Working Environment | temperature: -10℃-40℃ | |

| humidity | 30-90%RH (no condensation) | |

Application

Our collaborations with industry leaders such as Wanglaoji, Budweiser, SMC, and Schneider Electric further attest to the exceptional quality and dependability of our X-ray Liquid Level Inspection System. Investing in our product will enhance your quality control processes, reduce waste, and ensure customer satisfaction with every product.

Main Components

Manufacturing

Our Customers

Certifications

Pусский

Pусский

+86 13751397283

+86 13751397283