Product Introduction

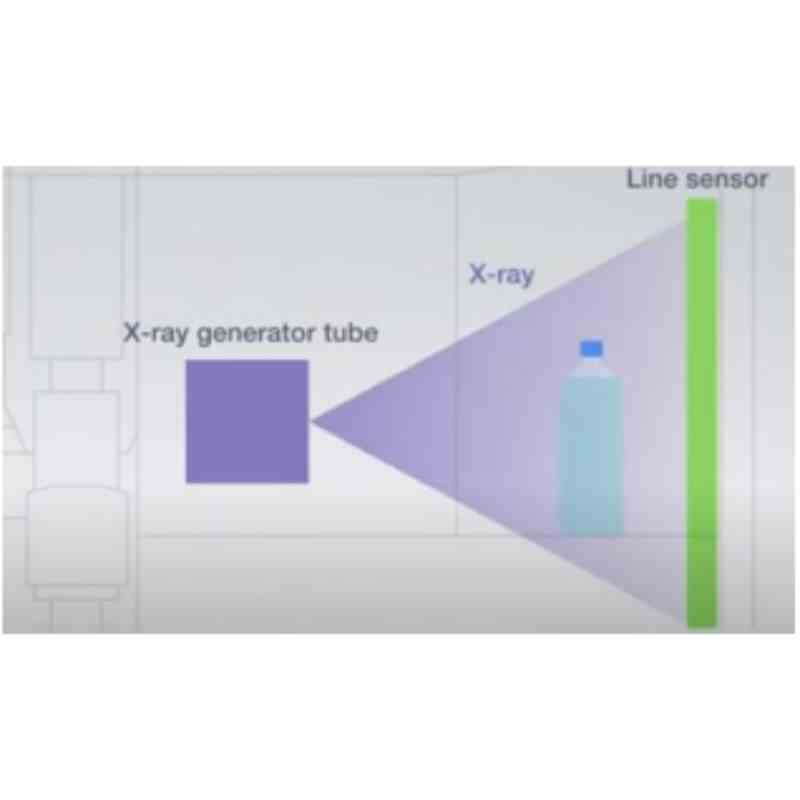

The JZXR XR-5000D Series is a cutting-edge X-ray inspection system designed to detect contaminants in bottled, canned, and jarred products. Utilizing side beam detection technology, it ensures superior foreign body identification, including metal (Ferrous, Non-Ferrous, and SUS), glass, ceramics, stones, and other high-density contaminants, even in metallized packaging.

Specification

| Specifications: | |

| Model: | XR-5000D |

| X-ray Source: | Standard: 240w,100kv.(optionat 350W,100kV) |

| X-ray Beam Direction: | Single X-ray beam from the side |

| Detector. | 0.4mm |

| Detection Tunnel Size: | 220mm (\)x 350mm (H).Customized order is acceptable. |

| Max. Detection Accuracy without product (150WX-ray Source): | SUS:≥Φ0.4mm,Ceramic:≥Φ1.2mm,Glass:≥Φ1.5mm |

| Conveyor Speed: | 20-80 m/min |

| Bearing Capacity: | Standard:s5 Kg.Customized order is acceptable. |

| O/S: | Win 10 |

| Software: | JZXR X-ray Inspection Software |

| Connectivity: | LAN port & USB port |

| Screen: | 21.5 inch full color touchable screen |

| Parameter Adjustment: | Auto Setting & Manual Setting |

| Operation Language: | Chinese & English |

| Reaction to defectives. | buzzer and red light alarm once foreign body is detected |

| Auto rejection system with SUS bin | Included |

| Material of construction: | SUS 304 |

| Surface Treatment | Mirror Polished / Brushed |

| Cooling Mode: | Industrial cooling fans & industrial AC |

| Working Environment: | temperature:-5℃C-40℃; humidity: 30-90%RH (no condensation) |

| Power Supply: | AC220V+10% 50160Hz |

| Safety: | |

| X-ray Leakage: | <1uSv/h (Meet FDA and CE standards) |

| Protective Mode: | 6 layers ofnon-lead food grade soft curtain |

| Conveyor Materia | Food grade PU belt with FDA certificate |

| lEmergency Stop Button | Yes,included |

| Multi-levels management | Yes, Operator, Worker and Administrator three -levels management to meetdifferent operation authority |

| Peripheral lndicator | The peripheral indicators are used to detect the operating status of external equipment. When the external equipment is normal or abnormal, the corresponding detection result icons will be displayed, and the abnormal parts will be displayed inthe device structure diagram to facilitate investigation. |

Application

Food & Beverage Industry: Ensures product safety in bottled juices, canned foods, sauces, dairy products, and more.

Pharmaceutical Industry: Detects contaminants in medicine bottles and health supplement packaging.

Manufacturing Quality Control: Ideal for automated production lines requiring strict contaminant detection.

With its high precision, reliability, and ease of use, the JZXR XR-5000D is the ultimate solution for food and beverage manufacturers looking to maintain the highest safety and quality standards.

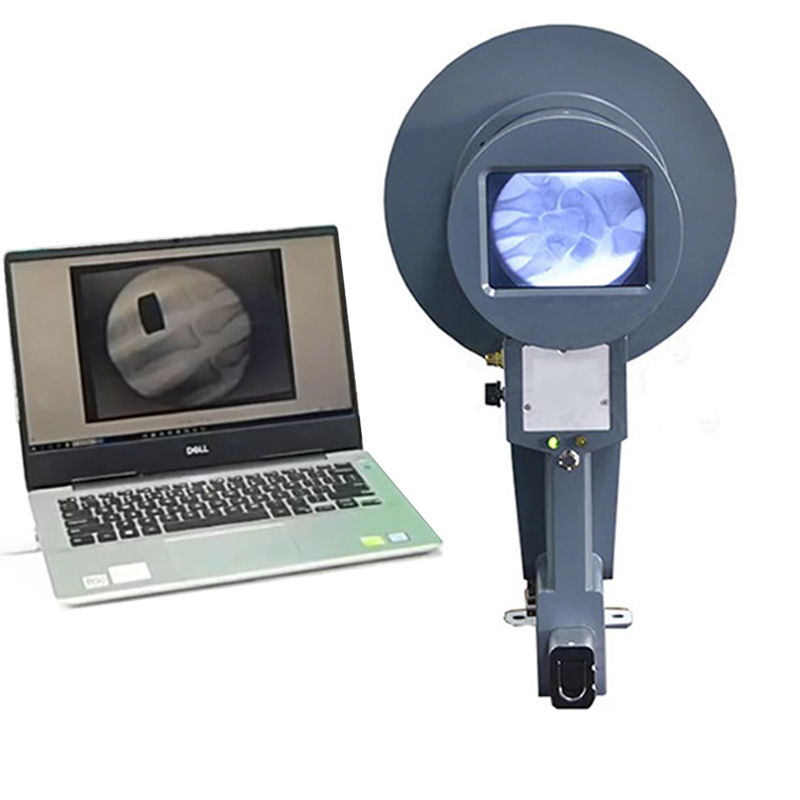

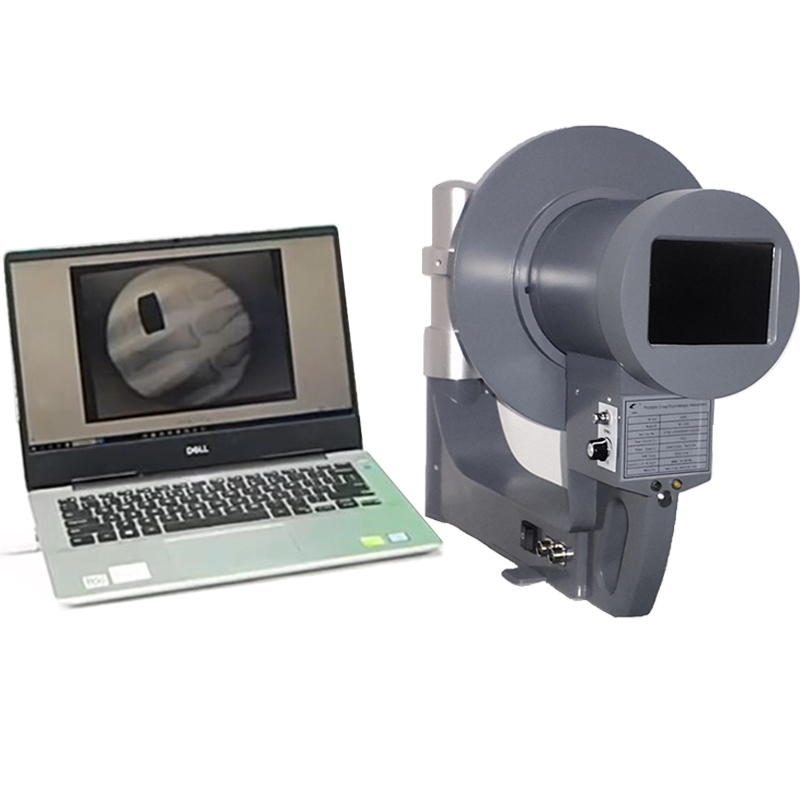

Main Components

Manufacturing

Our Customers

Certifications

Pусский

Pусский

+86 13751397283

+86 13751397283