Product Introduction

XR-180C-1 SUS 304 Vertical Fall Metal Detection System

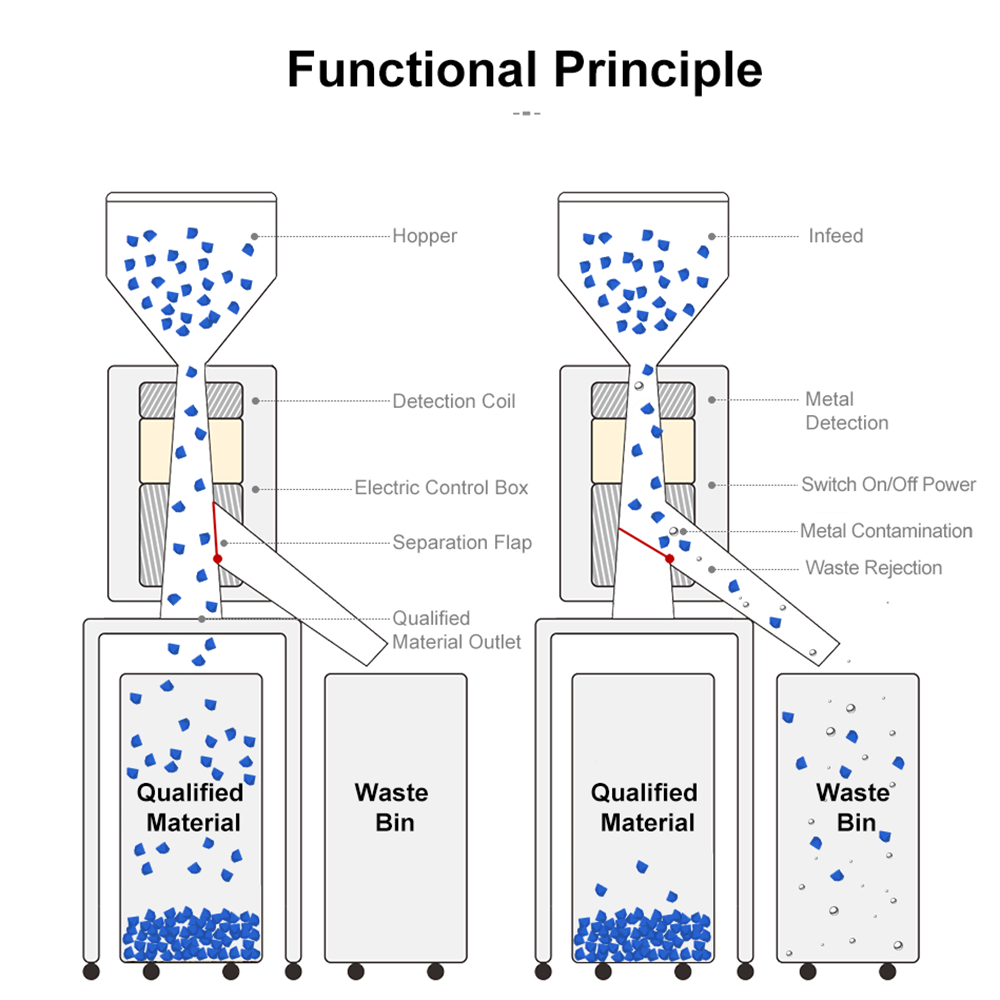

The XR-180C series Gravity Feed Free Fall / Throat Metal Detector Metal Separator is designed for inspecting powders, granules or bulk food products. The XR-180C metal detector unit with separation flap rejection system, and it is an ideal metal detection system for checking early in the production process to detect all metal contaminations before the product moves down the line, and minimising the potential cost of wastage and protecting other processing equipment. In this category the system will be having configuration ranging from 25 mm Dia., to 250 mm Diameter of pipeline, which can meet multi-application requirements. Juzheng metal detectors help you meet QS, HACCP, IFS, BRC and GMP requirements.

Features:

- Easy to use

- Small occupied space

- High detection accuracy

- Easy cleaning and maintenance

Specification

| Model | Pipeline Diameter (Φmm/In) | Detection |

Air compression (Bar) |

Max.Capacity (L/H) |

Temperature Range (°C/°F) |

Contaminations Rejection Time (Seconds) |

Installation Height (mm) |

|

| Accuracy | ||||||||

| (Φmm) | ||||||||

| Fe | SUS | |||||||

| XR-180C-1-25 | 25mm | 0.2 | 0.4 | 3-5 Bar | 300 |

-5-40°C / 23-04°C |

0.3-5 S | 330 |

| /9.84'' | ||||||||

| XR-180C-1-35 | 35mm | 0.3 | 0.5 | 400 | 330 | |||

| /13.78'' | ||||||||

| XR-180C-1-50 | 50mm | 0.5 | 1 | 2000 | 330 | |||

| XR-180C-1-70 | 70mm | 0.7 | 1.2 | 5000 | 330 | |||

| XR-180C-1-100 | 100mm | 1 | 1.5 | 12000 | 475 | |||

| XR-180C-1-120 | 120mm | 1.2 | 2 | 16000 | 475 | |||

| XR-180C-1-150 | 150mm | 1.5 | 2.5 | 25000 | 600 | |||

| XR-180C-1-200 | 200mm | 2 | 3 | 40000 | 920 | |||

| XR-180C-1-250 | 250mm | 2.5 | 3.5 | 60000 | 950 | |||

1. The above detection accuracy is the result without materials. The real detection accuracy would be affected according to the material being detected and the working environment.

2. The maximum detection capacity per hour is related with product weight and liquidity, the value of above data sheet is according to the density of water.

3. As our models will continue to be upgraded, please contact with our sales team for the more technical parameters and metal detection solutions.

4. Customized orders are acceptable.

Application

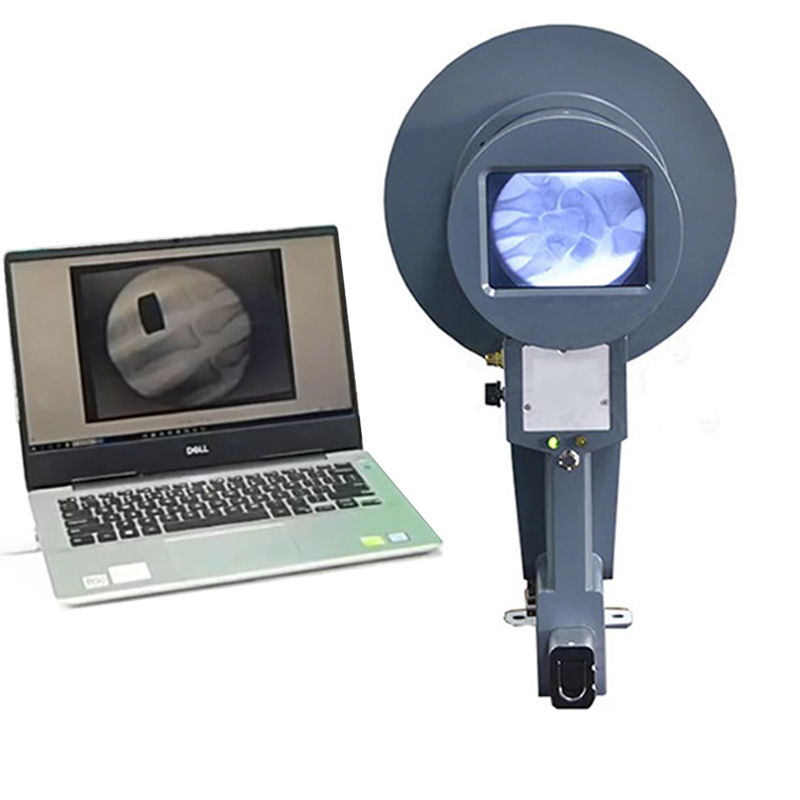

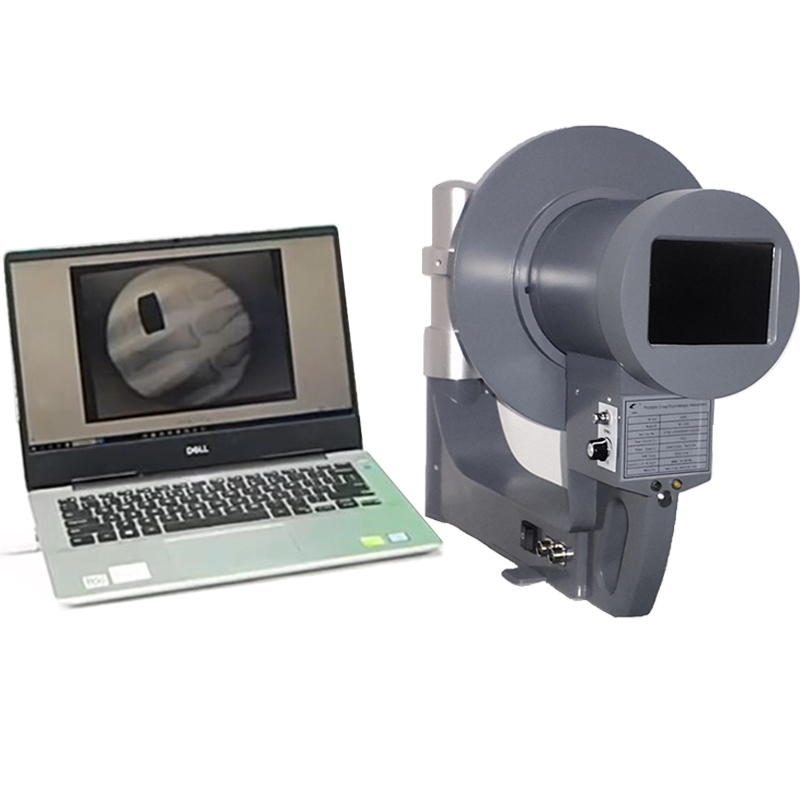

Main Components

Manufacturing

Our Customers

Certifications

Pусский

Pусский

+86 13751397283

+86 13751397283