Product Introduction

1.This advanced bulk food X-ray inspection system distinguishes itself from single-unit machines by incorporating a vibration feeding system, specifically designed to detect foreign contaminants in unpackaged food products.

2.The vibration feeding system ensures uniform distribution of products on the conveyor belt, enhancing detection accuracy and efficiency.

3.Capable of identifying contaminants such as metals, glass, stones, and dense plastics, this system ensures product purity and safety.

4.Equipped with a user-friendly touchscreen interface and high-speed data processing capabilities, it is well-suited for high-volume production lines.

Specification

| Model | XR-3500D |

| X-ray Generator | 80kV,350V |

| Rejection | 72 tunnel air jet rojectors |

| Tunnel size(W'H) | 600*100mm |

| Max sensitivity | Stainlosssteel ball:φ0.3mm,Coramics/Glass ball:φ1.0mm |

| Conveying speed | 10-120m/min |

| Screen | 17'' Full touchablo screen |

| X-ray direction | From the Top |

| O/S | Windows7 |

| Working environment | Temperature:-10-40C(Cooling:industrial air condition) Humidity:30%-90%,No frost(humidity control:dehumidifier) |

| X-ray leakage | <1uSv/hour |

| Protective mode | Protective soft curtain(removable) |

| Alarm | Soundand and light alarm,reject |

| Air pressure | 0.8Mpa |

| Power supply | AC220V,+10% 50/60Hz |

| Materlal of construction | SUS304 |

| Feedingsystem | Two motors of vibration feeding system |

Application

-

Nuts and Seeds Processing: Detects foreign contaminants in bulk nuts and seeds before packaging, ensuring product quality and consumer safety.

-

Grains and Legumes: Identifies metals, stones, and other foreign materials in bulk grains and legumes, preventing contamination.

-

Frozen Fruits and Vegetables: Inspects bulk frozen fruits and vegetables for contaminants prior to freezing or packaging, ensuring product purity.

-

Confectionery and Snacks: Ensures the absence of foreign objects in bulk confectionery and snack items, maintaining brand reputation and consumer trust.

-

Other Bulk Food Products: Suitable for various bulk food items requiring high-precision contaminant detection to meet food safety standards.

By integrating the vibration feeding system into the X-ray inspection process, this equipment offers enhanced detection accuracy and efficiency, making it particularly suitable for bulk food production environments that demand stringent quality control.

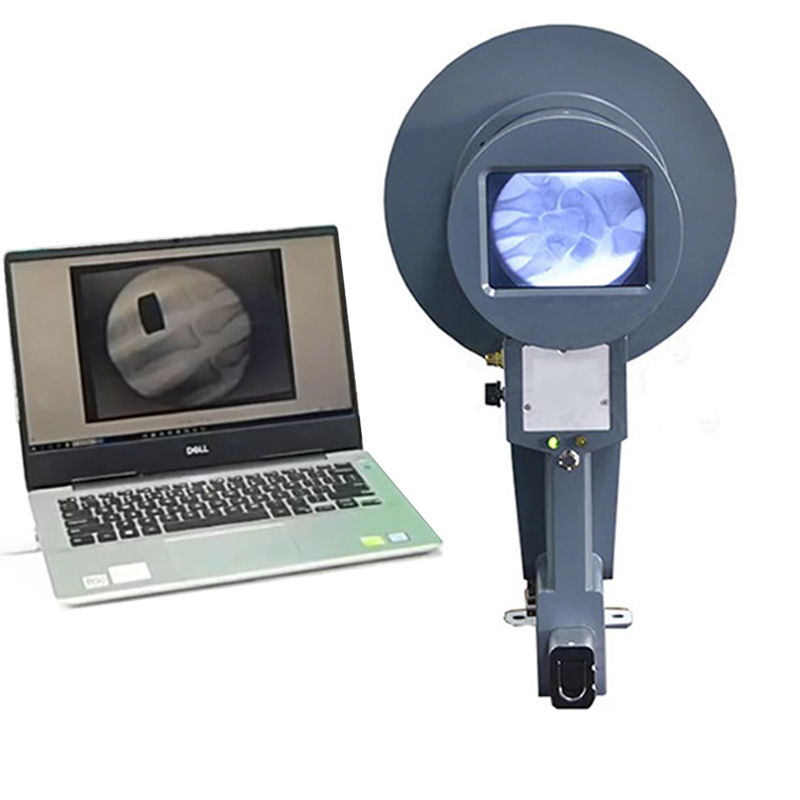

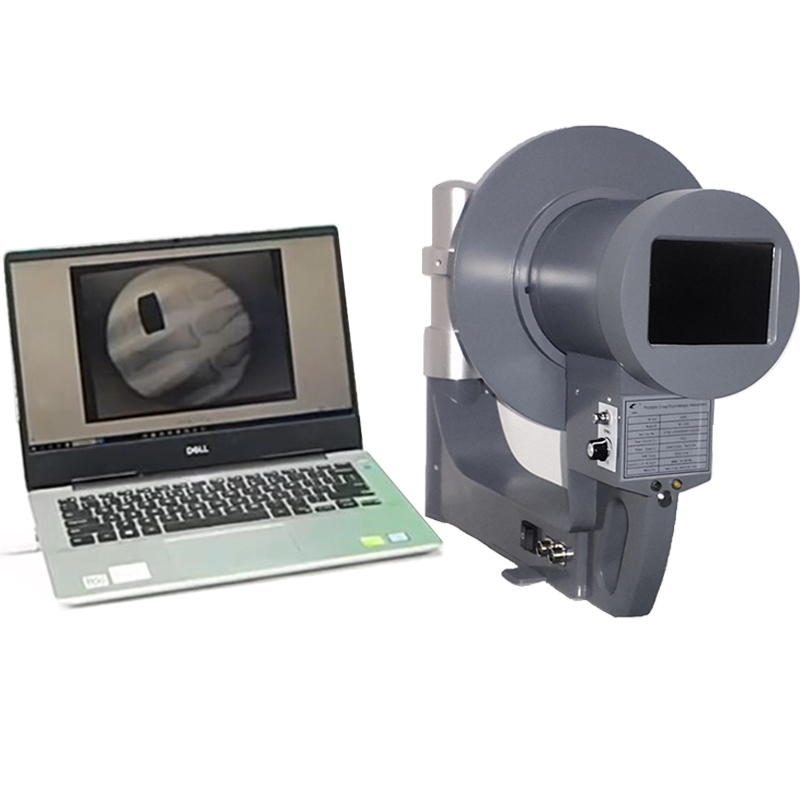

Main Components

Manufacturing

Our Customers

Certifications

Pусский

Pусский

+86 13751397283

+86 13751397283